I can move that screw around to different locations and the holes and all the different plates move with it. I can then use the pocket command to automatically cut the clearance holes, the tapped holes, for that fastener and all those plates automatically and associatively.

I can add it between three or four different plates. In the presentation we also covered the pocket command.In the Wizard software, if I were to add a screw into an assembly, it knows the size of the screw and knows the threads of the screw. The Bill of Materials will update, the detailed notes will update, and that makes me a happy camper! And, it is all associative, if I make a change in the design, all those sheets will update. The least amount of time I must type it, the less chance there is for error.

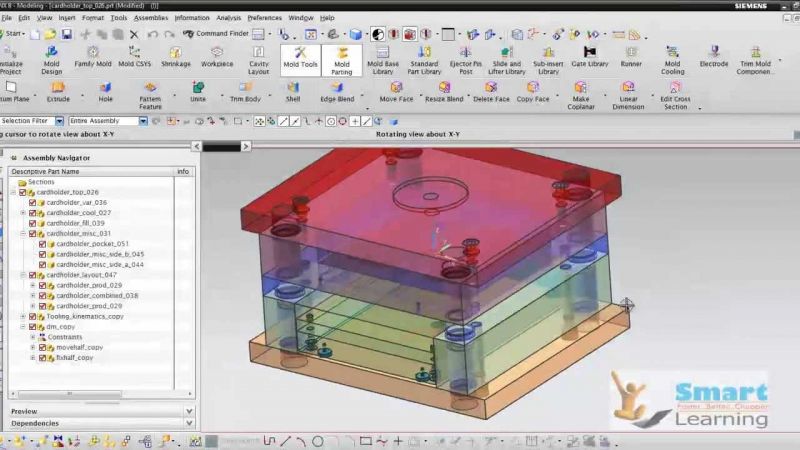

#UG NX MOLD WIZARD HOW TO#

Today I demonstrated how easy the automation is and how to leverage it even so far as using it for detailed notes on detailed drawings. It is all build into the system, so we don’t have to type them repeatedly. Mold Wizard and Die Wizard have captured a lot of these descriptions, titles and materials, part numbers, and suppliers. The Bill of Materials automation greatly reduces the amount of typing, increases the accuracy of the part numbers, material sizes. Every design has a Bill of Materials for purchasing the different components to build that mold and or die. One of the items I covered in the presentation was the Bill of Materials. I described how to leverage them for the automation ntent that they have. But, they all have common functions that I highlighted in my presentations, and how they are the same across all of them. There is also Stamping Die Wizard – a little bit different yet from the Progressive. Progressive Die Wizard is very similar although it is a whole different discipline. I am an expert in the Mold Wizard product. The products have a lot of similarities between them. My presentation at Realize LIVE 2019 was on the twin wizards that Siemens has developed over the years. I was involved for 20 years and find this to be very valuable to learn new things and get training. For the local event I was the president of the Chicago-area user group for the past six or seven years. The national event used to be called PLM World. I’ve been coming to Siemens user events for about 12 years. I design plastic injector molds, diecast dies, and other types of tooling items. Kevin Jongsma, NX Designer and Programmer, from Intelligent Design and Services, shares his best practices in tooling wizards, Mold Wizard and Die Wizard. Watch this video to get his tips and tricks and let us know what you think in the comment section below.

0 kommentar(er)

0 kommentar(er)